Manufacturing Process

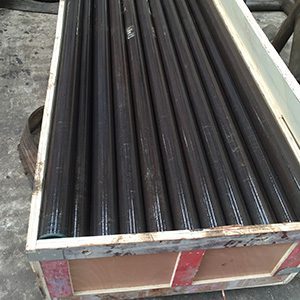

Cold drawn seamless tube and pipe are manufactured through a process that begins with piercing hot billets. This initial step is followed by rolling, which serves to decrease their diameter and simultaneously extend their length. The material is then meticulously passed through a die while being guided over a mandrel plug. This critical phase of the process ensures the achievement of precise dimensions and the correct gauge, encapsulating the core of the cold drawing technique.

Benefits Of Cold Drawn Seamless Tube

- Enhanced Strength & Hardness Properties: Offers superior structural capabilities and resistance to wear and tear.

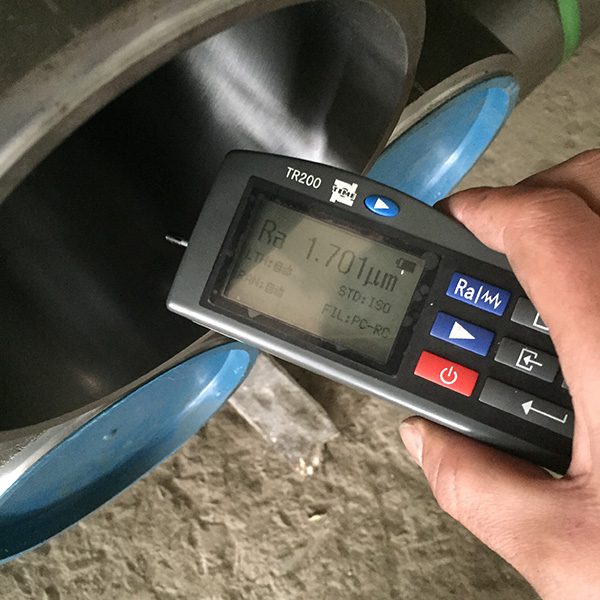

- Precision in Size: Ensures exact dimensions for reliable performance and fit.

- Improved Aesthetic Quality: Features a refined finish for a professional look.

- Consistent Micro-Structure: Guarantees uniform mechanical properties throughout the material.

- Machinability: Facilitates easier and more efficient machining processes.

- Tight Tolerances: Minimizes the need for extensive machining, reducing time and cost.

- Potential for Spiraling Eccentricity: An inherent characteristic of the product, highlighting the precision in manufacturing.

Applications Of Cold Drawn Seamless Tubes

- Applications: Ideal for a diverse range of uses including petrol, gas, water pipelines, construction projects, and fluid transport. Additionally, it’s exceptionally suited for high-pressure applications, such as High-Performance Liquid Chromatography (HPLC).

- Hydraulic Systems: An essential component for the efficient operation of hydraulic systems.

- Foundation of Honed Tubes: Serves as the basis for all honed tubes, highlighting its versatility and importance in manufacturing.

- Pressure Resistance: Engineered to withstand internal pressures, ensuring durability and safety in demanding environments.

- Cylinder Production: Integral to the manufacture of cylinders, reflecting its strength and reliability.

- Hydraulic and Pneumatic Applications: Perfectly suited for both hydraulic and pneumatic systems, emphasizing its broad utility in industrial applications.

Our main business range is listed as follows:

Ready to hone tube

ST52 Honed tube

Pre Honed Tubes

Hydraulic Cylinder Barrel

Carbon Seamless Steel pipe/tube

Hydraulic cylinder tube(Honed tube)

Hard chrome plated rod/bar/shaft(Piston rod)

Hydraulic cylinder

Want to purchase Our clod drawn seamless tube?

Please contact us through below methods for more information.