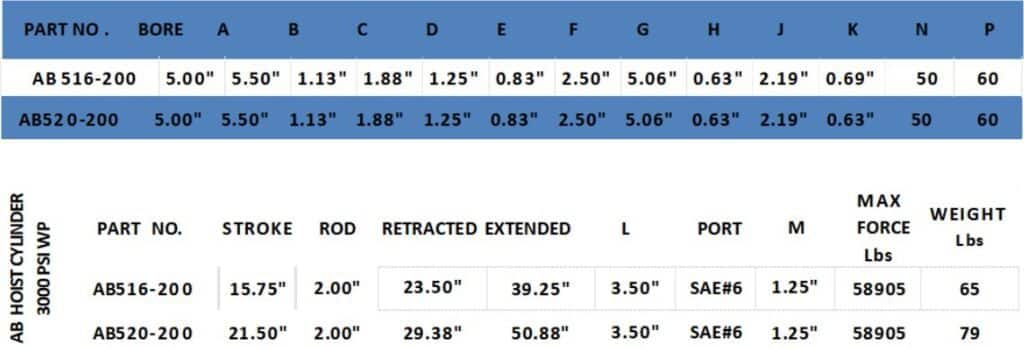

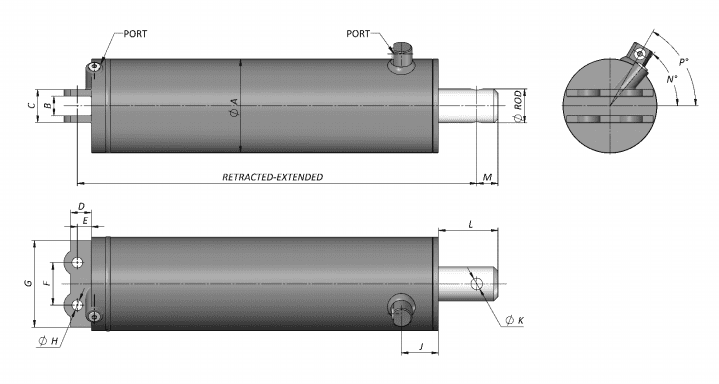

DIMENSIONAL CHART

Stroke: 50mm—16000mm

Inside Cylinder Tube Dia: 40 – 1000 mm (1.5 – 40 inch)

Liner material: Copper (prolongs the life cycle of the cylinder)

Hydraulic cylinder tube material: Carbon steel, Alloy steel, Stainless steel

Piston Rod Dia: 12 – 500 mm (1/2 – 20 inch) Hydraulic Piston Rod should be hard chrome plated to a minimum thickness of 35-55 microns and polished to 0.15 um Ra

Chrome Plated: Cr, Ni, or Ceramic

Design Pressure: Max 700 bar (10150 PSI)

Valves: SUN (USA), or a reputable Chinese brand with the same quality as PARKER

Seals Type: PARKER (USA), MERKEL (Germany), or NOK (Japan)

Liner material: Copper (prolongs the life cycle of the cylinder)

Bearings: LONGXI (China) or SKF

Painting: Follow customer requirements or 3-coat marine painting

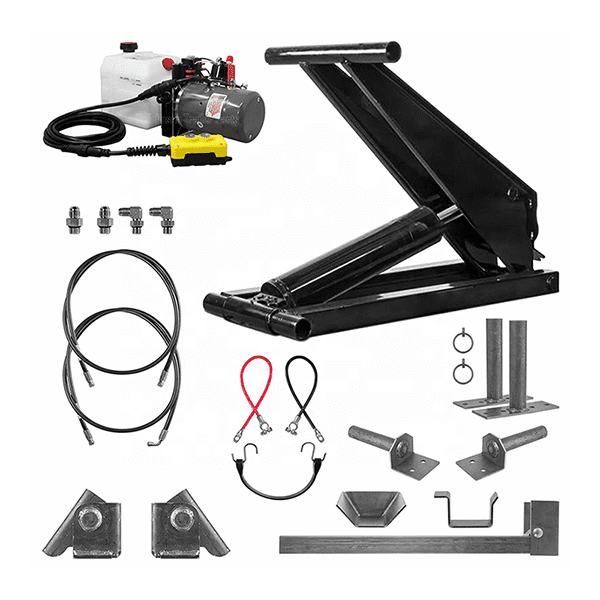

Application: Shipbuilding, offshore oil & gas engineering, Photovoltaic & wind power, construction machinery (excavator, loader, crane, snowplow, sanitation vehicle), agricultural machinery, hydraulic engineering, heavy machinery